CREEP LIFE EXTENSION OF A SINGLE CRYSTAL SUPERALLOY

BY RE-HEAT-TREATMENT

Y.Koizumi, T.Kobayashi, H.Harada and T.Yamagata*

* High Temperature Materials Research Group

National Research Institute for Metals, Tsukuba Science City, Japan.

Published in Proceedings of the Fourth International Charles Parsons Turbine Conference on

"Advances in Turbine Materials, Design and Manufacturing", held at Newcastle upon Tyne, UK,

4-6 November 1997, pp. 679-684. The Institute of Materials.

ABSTRACT

- Effect of re-heat-treatment on the remnant creep life of a single crystal (SC) superalloy was investigated. It was found that the microstructure and the creep strengths of SC samples crept up to the early tertiary creep stage can be recovered by a re-solution treatment followed by two-step ageing treatment. The sample crept up to mid tertiary creep stage, however, was recrystalised during the solution treatment, resulting in a very low creep strength due to rupture at the created grain boundary. These results show that a simple re-heat-treatment can effectively improve the cost performance of SC components. This is in contrast with the case of conventionally cast (CC) alloys which needs hot isostatic pressing to eliminate the creep voids formed at grain boundaries.

INTRODUCTION

- The service life extension of gas turbine components is becoming increasingly important especially with single crystal (SC) superalloy turbine blades and vanes. As their production costs are becoming higher due to the complex process conditions and expensive alloying elements being used, it is of vital practical importance to establish the methodology of rejuvenation for the SC superalloy components after high temperature services causing creep damages.

- In the case of conventionally cast (CC) superalloys, the creep damage occurs first as the microstructure changes such as coarsening and coalescence of �$B&C�(B' precipitates, which is followed by void formations at grain boundaries. Thus normally hot isostatic pressing (HIP) is needed to eliminate the creep damages [1], although the perfect microstructure recovery is not always possible due to the presence of grain boundary strengthening elements, i.e., carbon and boron, which decrease the incipient melting temperatures to prevent perfect solutioning of the �$B&C�(B' phase. In contrast with these, creep void formation does not occur in SC superalloys due to the absence of grain boundaries which provides the void formation site. Also, SC superalloys can be fully solutioned at high temperatures due to the absence of the grain boundary strengthening elements. Thus we expected that the creep damage in SC superalloys can be eliminated by a simple re-heat-treatment.

- In the present study we examine the effect of a re-heat-treatment on the remnant life of an experimental SC superalloy, expecting the microstructure recovery and the creep life extension. The effect of the prior creep deformation extent was examined in connection with a possible recrystalisation tendency during the re-heat-treatment.

EXPERIMENTAL PROCEDURE

- An experimental SC superalloy TMS-17, Ni-6Cr-10W-5Al-11Ta in wt%, designed by us using our alloy design computer program [2, 3], was cast in DS furnace to SC bars of 10 mm dia having longitudinal directions within 5 degrees of <100>. The bars were fully solution treated at 1345�$B!n�(B for 4 h, followed by an ordinary two-step ageing treatment, first at 1080�$B!n�(B for 5 h and second at 870�$B!n�(B for 20 h, both followed by air cooling.

- The creep rupture test was performed with using test pieces of 4 mm dia and 20 mm gage length. The testing condition was at 1080�$B!n�(B and at 137 MPa. The creep behaviour was monitored with a total length of the sample and thick shafts outside the furnace. The test was interrupted with three samples at different creep stages, i.e., mid secondary, early tertiary and mid tertiary stages. The samples were cooled in the furnace under stress and then unloaded. They were re-heat-treated in quartz tubes filled with argon under the same heating condition as above, except for the heating time of solution treatment being 0.5 h instead of 4 h. Oxidation affected surface layer was removed by a careful grinding to make the samples back to the cylinder shape. The samples were again tested under the same creep condition to rupture. Microstructures in specimens before and after the creep tests were observed by using scanning electron microscopy (SEM). Laue X-ray back reflection analysis was used to determine the crystallographic orientations in ruptured samples.

RESULTS AND DISCUSSION

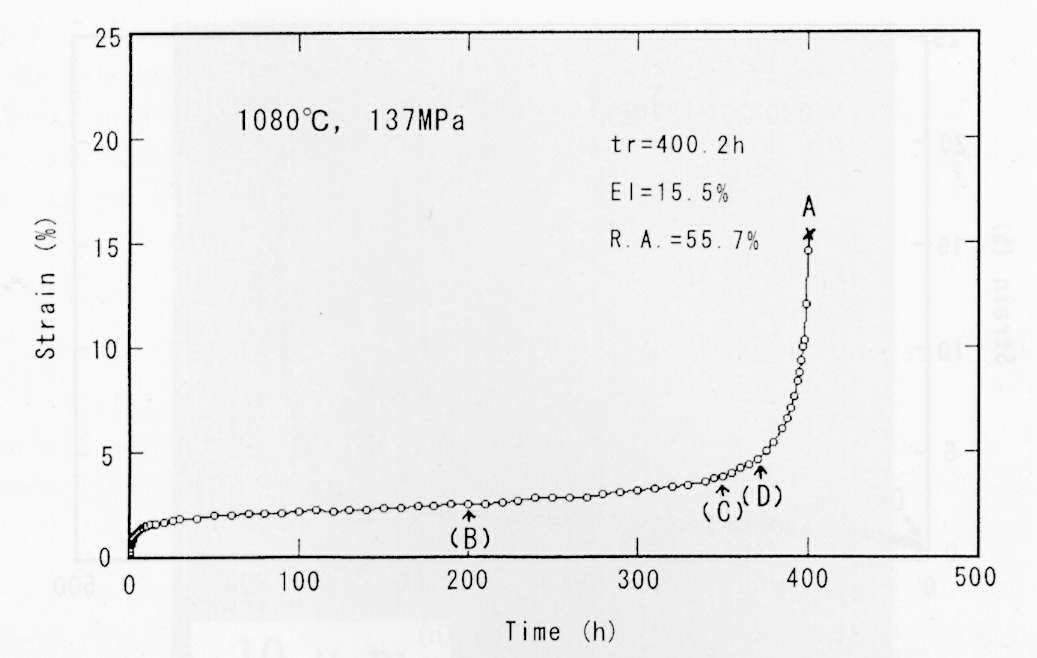

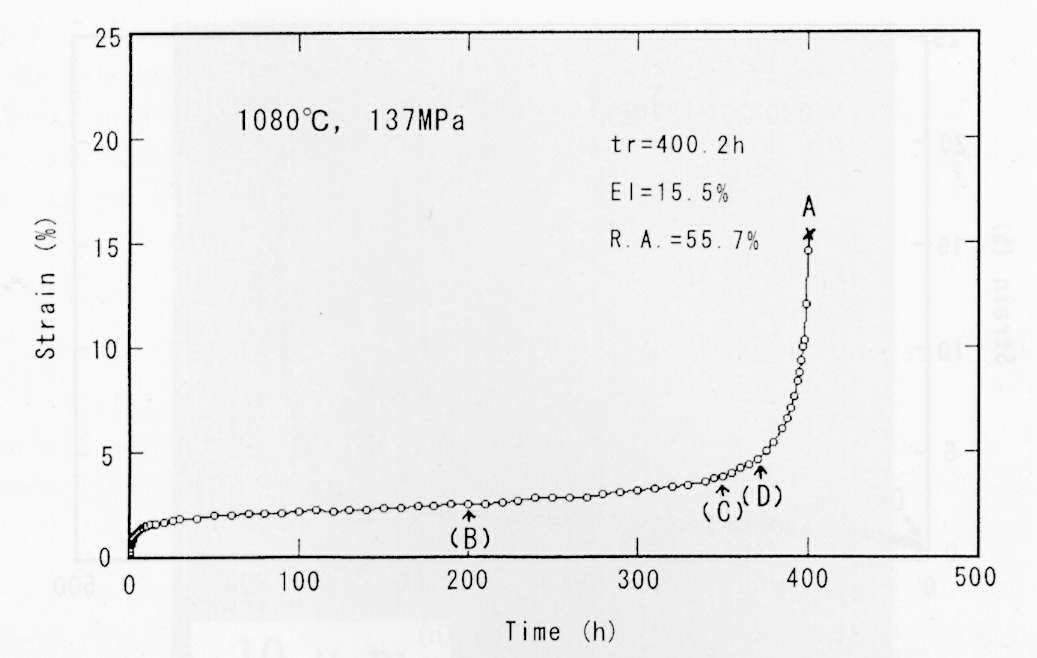

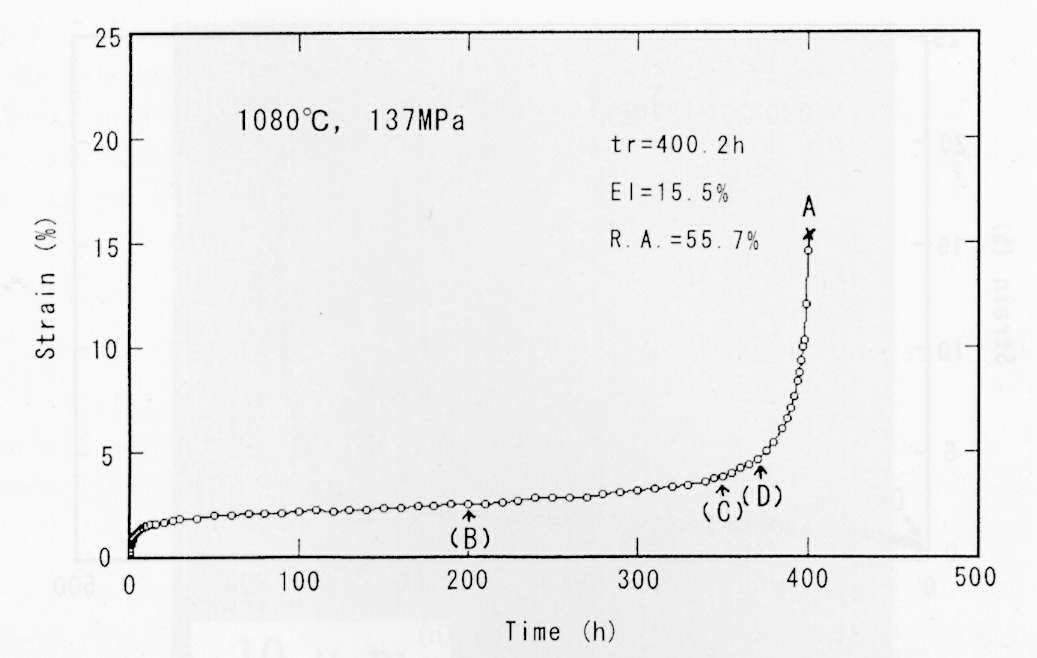

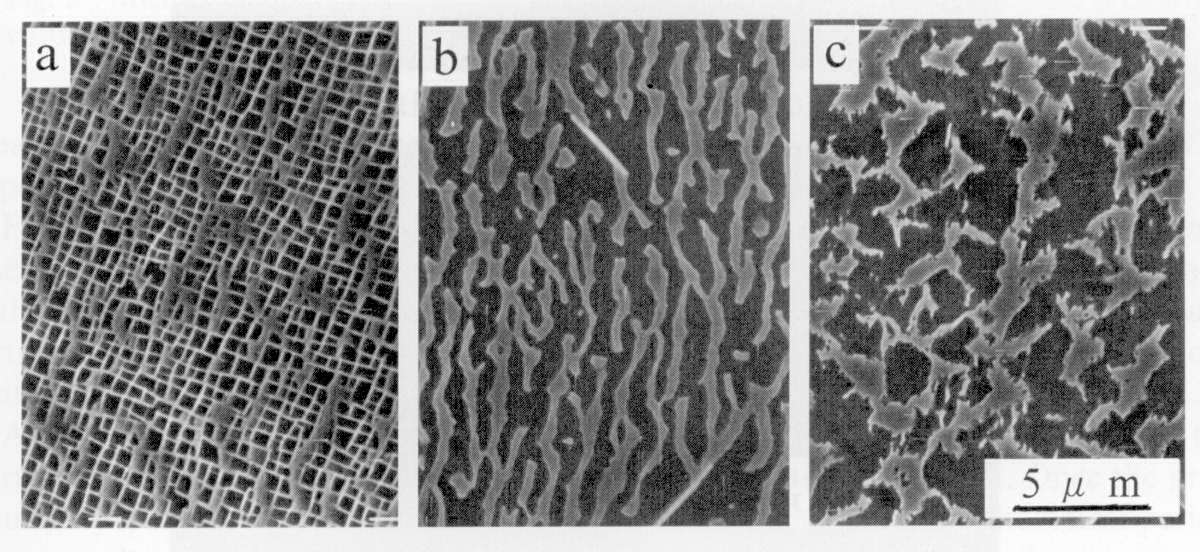

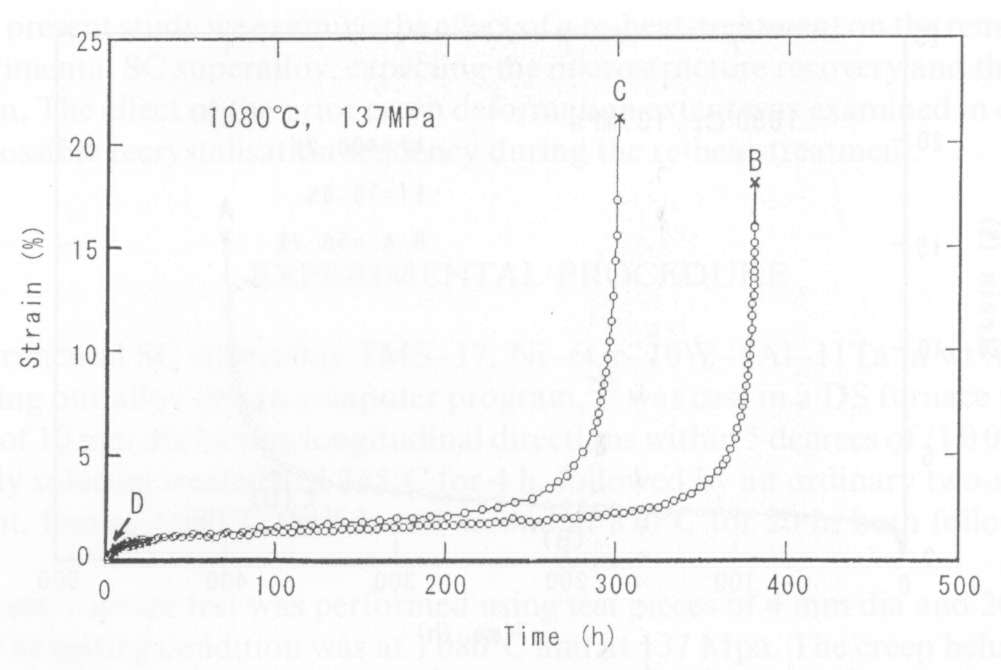

- A typical creep curve of TMS-17 is shown in Figure 1. The creep rupture life obtained is about twice as long as that of CMSX-4 [4] at this testing condition. The microstructures in the sample A is shown in Figure 2. These photographs show that the shape of �$B&C�(B' precipitates changes from original cuboidal shape (a) in as heat treated sample to so-called rafted structure during creep. The rafted structure maintains the secondary creep with a very small creep rate until the raft is eventually sheared (b) and degenerated (c) on the tertiary creep stage [5]. This is a typical creep deformation of SC superalloys under higher temperature and lower stress conditions. The creep deformation of the other samples interrupted at points corresponding to B, C and D, were directly measured to be 1.0, 2.1 and 3.0% in elongation and 0.1, 1.0 and 3.3% in reduction of area (R.A.), respectively.

- Figure 1 A typical creep curve of TMS-17. The creep test was interrupted for other three samples at (B), (C) and (D).

- Figure 2 Microstructures in as heat treated (a) and ruptured (b and c) sample A, (b) at 4 mm and (c) within 1 mm distance from the rupture surface

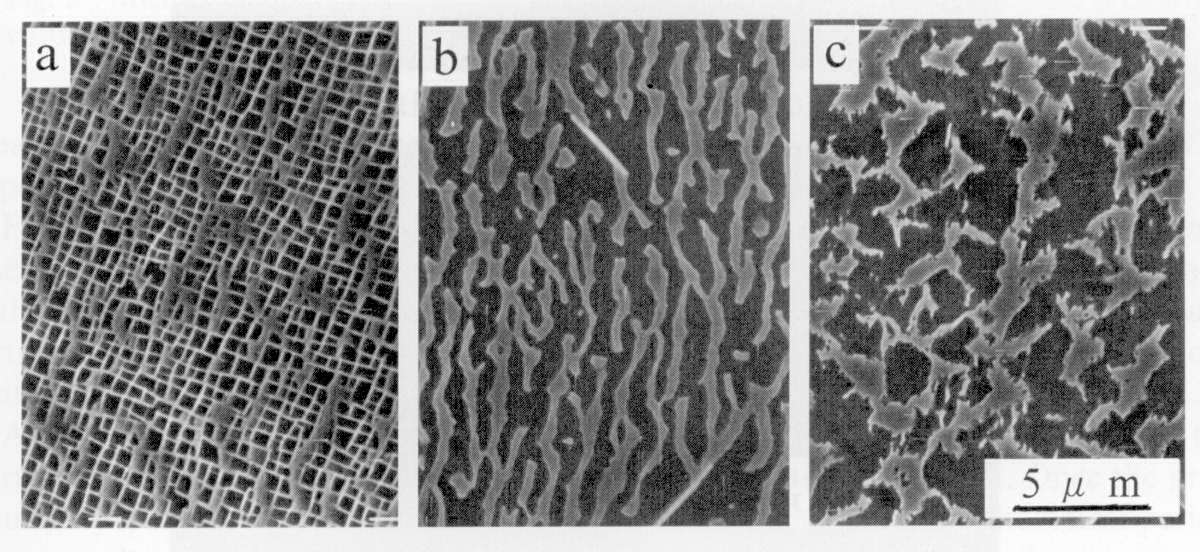

- The interrupted samples were tested at the same creep stress and temperature condition after the re-heat-treatment followed by the careful surface grinding. The creep curves obtained are shown in Figure 3. The sample B, which was crept up to the mid secondary creep stage, exhibits the same creep strength as the original sample. The sample C which was crept up to the early tertiary creep stage also has almost the same level of creep strength. In contrast with these, the sample D, which was crept up to the mid tertiary creep, was ruptured in a very short time period, the rupture life being 0.08 h. The rupture elongation was 0.3%. The rupture surface was smooth.

- Figure 3 Creep curves of the interrupted and re-heat-treated samples B, C and D.

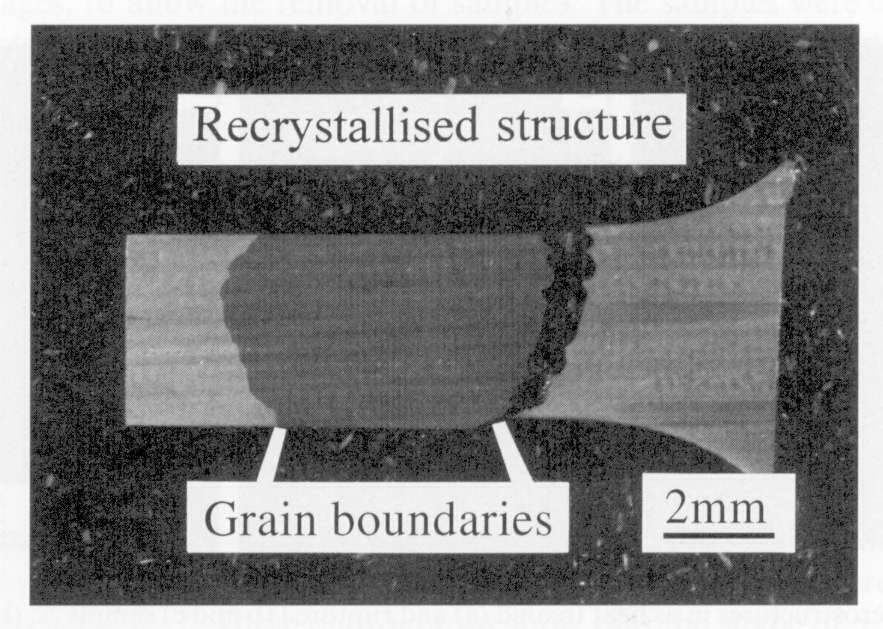

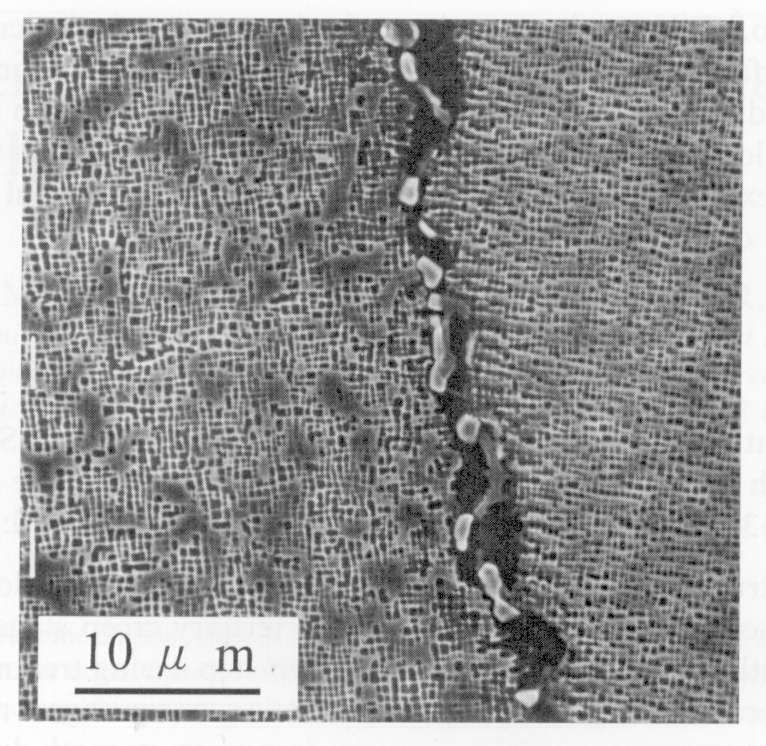

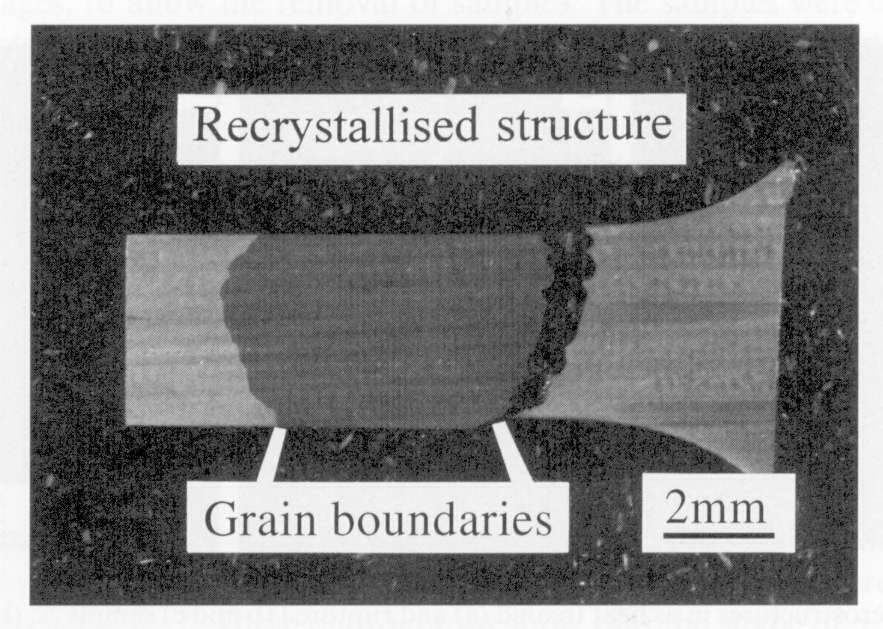

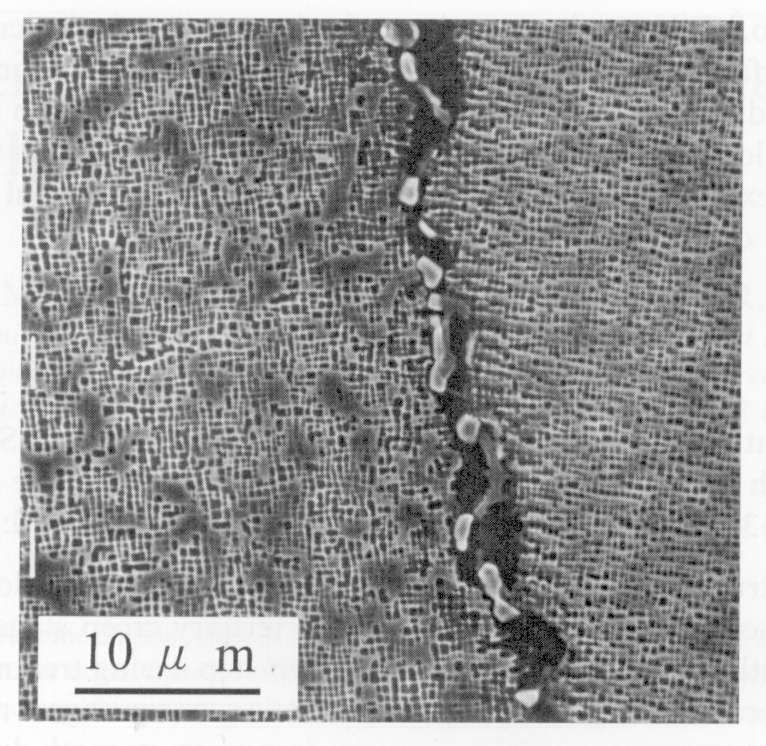

- Figure 4 is a macroscopic observation of the longitudinal section in ruptured sample D. This photograph shows that the sample deformed up to the mid tertiary creep stage was recrystalised to become a so-called bamboo structure by the re-heat-treatment. The rapture occurred at one of the created grain boundaries. The microstructure of the grain boundary is shown in Figure 5. A crystallographic misorientation at the boundary is clearly visible from the alignments of�$B&C�(B' precipitates in the two grains. The Laue X-ray back reflection analysis xxxx showed the misorientation is about 8 degrees, by which the boundary is characterised as a normal large angle boundary rather than a low angle one. The grain boundary provides a precipitation site as seen in Figure 5. The bright contrast in SEM image reveals that the precipitates contain heavy alloying elements, presumably W and Ta. This type of precipitates normally strengthen grain boundaries. Even so the creation of the large angle grain boundary is found to be fatal to the creep strength of SC superalloys.

- Figure 4 Macroscopic observation of the longitudinal section in the ruptured sample D, showing the recrystalisation occurred during re-solution treatment and the resulting creep rupture at the created grain boundary.

- Figure 5 Microstructure of the grain boundary. The crystallographic misorientation is clearly visible from the �$B&C�(B' alignments in the two grains..

- From all the results obtained, it is considered that the microstructure and, consequently, the creep strength of SC superalloys can be fully recovered by re-heat-treatment if the prior creep deformation is small enough to be in secondary or in early tertiary creep stages. If the prior creep deformation is on the stage of mid tertiary or beyond that, a localised deformation or necking has started to occur as was measured to be 3.3% R.A. with the sample C. This causes the strain energy storage and the lattice rotation in this part, which drive the recrystalisation during the re-solution treatment. Once the grain boundary is created, the sample is ruptured at the boundary in a very short time period. These results show that the creep life extension is possible by a simple re-heat-treatment with SC components used up to the secondary or, marginally, the early tertiary creep stage.

- The investigation so far are carried out with a high temperature and low stress condition for the prior creep deformation. In this condition, as mentioned before, the rafting occurs to prolong the secondary creep. Almost 90% of creep life of TMS-17 is regarded as the secondary creep stage (see Figure 1) in which a uniform deformation occurs without making any localised deformation. Thus the re-heat-treatment was very effectively applied even to the sample at the 87.5% of its life, i.e., at C in Figure 1.

- Here a question may arise. Is this method applicable to the creep damage given at lower temperature and higher stress conditions also? Generally in such conditions rafting tendency is weaker and so the secondary creep does not clearly observed. Also, the creep behaviour becomes more sensitive to the tensile stress orientation especially when the alloy contains Co [6]. This may lead to a larger lattice rotation during creep. However, our observation so far with a number of creep testing in such conditions showed that the deformation tends to occur rather uniformly throughout the creep procedure without causing serious localisation or necking. Taking this into account the answer can be yes, although experimental verification is needed with careful attention to the crystallographic orientations of alloy samples.

CONCLUSIONS

- Effect of re-heat-treatment on the remnant creep life of the SC superalloy was investigated with using an experimental alloy TMS-17 under the creep condition at 1080�$B!n�(B and at 137 MPa.

The following results have been obtained;

- 1. The microstructure and the creep strength of the SC superalloy sample crept up to the mid secondary or, marginally, early tertiary creep stage can be recovered by a re-solution treatment followed by two-step ageing treatment.

- 2. The SC superalloy sample crept up to mid tertiary creep stage is recrystalised during the solution treatment, resulting in a very low creep strength due to the rupture at the created grain boundary.

- 3. Thus the re-heat-treatment after careful monitoring of the creep strain can effectively improve the cost performance of SC components through microstructure recovery from the creep damage caused by high temperature services.

REFERENCES

- 1. G.Blikstad, C.Persson, P-O. Persson and C-G. Samuelsson, Proceedings of Conference on High Temperature Materials for Power Engineering 1990, held in Liege, Belgium, 24- 27 Sept. 1990, Kluwer Academic Publishers, p.1131.

- 2. T.Yamagata, H.Harada, S.Nakazawa and M.Yamazaki, Trans. ISIJ, Vol.26 (1986), p.638.

- 3. H.Harada, K.Ohno, T.Yamagata, T.Yokokawa and M.Yamazaki: Superalloys 1988 (TMS AIME), p.733.

- 4. D.J.Frasier, J.R.Whetstone, K.Harris, G.L.Erickson, and R.E.Schwer, Proceedings of Conference on High Temperature Materials for Power Engineering 1990, held in Liege, Belgium, 24-27 Sept. 1990, Kluwer Academic Publishers, p.1281.

- 5. T.Yamagata, H.Harada, S.Nakazawa, M.Yamazaki and Y.Nakagawa, Superalloys 1984 (TMS AIME), p.157.

- 6. H.Murakami, T.Yamagata, H.Harada and M.Yamazaki, Materials Science and Engineering A223(1997), p.54.

go to Platinum Group Metals Home Page

go to High Temperature Materials 21 Project Home Page