We have developed Ir-base refractory superalloys. However the densities of the Ir alloys are much higher, 20-22 g/cm3, than those of Ni-base superalloys, 8.0-9.0 g/cm3. In terms of density, Rh is another promising candidate among the platinum group metals, having a slightly lower melting temperature (1960 C), smaller density (12.4 g/cm3) and better oxidation resistance than Ir.

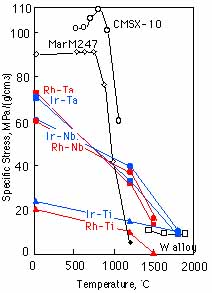

The compression strengths of Rh-15at%X (X= Ti, Ta, and Nb) binary alloys at temperatures between room temperature and 1500 C were investigated. 0.2% flow stresses of as-cast alloys are shown in Fig. 1. The 0.2% flow stresses of a Ni-Al-Cr alloy with 40% L12 phase(1), a commercially available Ni-base superalloy, MarM247 (Ni-10Co-10W-8.5Cr-5.5Al-0.7Mo-3Ta-1.4Hf wt%)(2), and the tensile yield stresses of a third generation single crystal Ni-base superalloy, CMSX-10 (Ni-2Cr-3Co-0.4Mo-5W-8Ta-6Re-0.1Nb-5.7Al-0.2Ti-0.03Hf wt%)(3) and of a W-base HfC dispersion hardening alloy (W-0.35wt%Hf-0.025wt%C)(2) are also plotted for reference. The strengths of the Rh-Nb and Rh-Ta alloys were equivalent to the strengths of MarM247 and CMSX-10 below 1000 C. The 0.2% flow stress of the 2 Rh-base alloys were above 400 MPa even at 1200 C and much higher than that of MarM247 (50 MPa) at that temperature. At 1500 C, the strengths of the 2 Rh-base alloys were about 200 MPa and they are equivalent to the strength of the W-HfC alloy (197 MPa), which had been the strongest known metallic material available at this temperature.

Although the strength of the Rh-base alloys is lower than those of the Ir-base alloys, the specific strength of both alloys are almost identical, since the density of Rh (12.4 g/cm3) is half of that of Ir (22.4 g/cm3) (Fig. 2).

The fcc and L12 two phase structures of these alloys heat treated at 1500 C for 1 hour were observed by scanning electron microscopy (Fig. 3). Precipitate shape of the Rh-Nb and Rh-Ta alloys are cube. Precipitate shape is not clear for the Rh-Ti alloys.

It was concluded that Rh-base alloys are also promising materials for high temperature use.